Enhanced cold-spraying capabilities will assist OEMs to cheaply meet new particulate emissions laws once they come into drive. By Werner Krömmer and Paolo Kirchpfening

Air high quality in mature economies—notably in main cities—is starting to profit from enhancements in emissions know-how related to the newest sustainable electrical propulsion automobiles. Nonetheless, the imaginative and prescient of an emissions-free driving future promised by electrical automobiles (EVs) just isn’t fairly as free from emissions some may consider.

In keeping with findings from the LOW environmental impression BRAke SYStem (LOWBRASYS) mission, brake put on can contribute as much as 55% (by mass) of all dangerous non-exhaust traffic-related emissions in excessive density city environments. These emissions include carbon-based particulate matter (PM) which emanates from the high quality mud created from braking. And that is as true for EVs as it’s for combustion-based automobiles.

Though car exhaust emissions in Europe have been considerably lowered, airborne particle emissions attributable to brakes and tyres stay a substantial environmental and well being difficulty, notably as the general variety of automobiles on the highway will increase. Each time car brakes are activated, tiny however dangerous steel particles produced by the abrasion of the brake pads towards the wheel are emitted.

Emission information from the UK Nationwide Atmospheric Emissions Stock (NAEI) estimate that non-exhaust emissions (NEE) at the moment are the dominant supply of each coarse and high quality particulate matter from highway transport within the UK. And automotive particulates contribute as much as 20% of all PM air pollution within the air, with the remainder coming from fires, energy vegetation, development websites and different industrial operations. The well being dangers associated to the miniscule airborne particles have been extensively studied and it has been demonstrated that they will attain the outer areas of the human lung and subsequently signify a extreme well being hazard. It’s particularly efficient in doing in order PM concentrates within the air near floor degree, at youngster peak. Along with their bodily properties. Brake emissions are usually sized within the PM10 vary (that may be a 10-micron diameter or smaller). At this measurement, it’s inhalable and related in measurement to pollen, however the particulates could be even smaller (on the PM 2.5 vary), making it even simpler to soak up.

In its 2022 report on air high quality, the European Atmosphere Company (EEA) acknowledged that “96% of the city inhabitants was uncovered to ranges of high quality particulate matter above the health-based guideline degree set by the World Well being Group.” It added that “publicity to concentrations of high quality particulate matter above the 2021 World Well being Group guideline degree resulted in 238,000 untimely deaths within the EU 27.”

Mud busting with subsequent era brake coatings

Whereas the European Parliament has agreed to delay stricter Euro 7 emissions till mid-2030—5 years later than deliberate—there’s little doubt that a few of the new requirements initially proposed in Euro 7 are shifting better deal with to non-exhaust emissions. In a extensively cited examine by impartial emissions testing firm Emissions Analytics, it was discovered that the better the car mass and propulsion torque, the better the quantity of particulate emissions. And with the typical EV housing half a tonne of battery weight, EV producers will inevitably be affected, regardless of the latest delay in stricter laws.

Whereas ceramic brake pads typically create much less brake mud in comparison with metallic ones (and the mud they do create is much less poisonous), they don’t signify a possible resolution for the typical client automobile as they don’t work effectively till they’re warmed up and at optimum performance. Consequently, their use is especially restricted to racing automobiles and a few excessive finish luxurious and efficiency automobiles.

A further problem is that because of the regenerative braking programs of EVs, brake utilization is often not as vigorous as present in combustion automobiles. With this lowered utilization, steel brakes are extra inclined to corrosion which might impression performance and security, doubtlessly leading to frequent disc modifications and even substitute of complete braking programs. The optimum resolution thus far is to coat brake discs with a mix of a steel alloy and ceramic powder—a really corrosion resistant materials mixture leading to a coating so there’s little to no resistance.

Thermal administration of warmth sinks in EVs

As EVs change into extra highly effective and incorporate bigger batteries, extra highly effective programs are wanted for higher cooling. Essentially the most superior automotive warmth sinks—primarily warmth exchangers that assist to switch warmth from the engine to the exterior setting—at the moment are usually hybrid fashions product of copper and aluminium. Historically they have been product of both pure copper or pure aluminium, however confronted both weight or manufacturing points. Whereas copper could be soldered, it’s heavy and leads to decreased driving vary; for each ten kilos a car can drive one kilometre much less. Equally, aluminium whereas lighter, can’t be soldered, inflicting challenges to environment friendly manufacturing.

By spraying a copper coating of between 100-200 microns onto an aluminium substrate, warmth sink producers benefit from the optimistic attributes of each supplies—permitting for 30% higher efficiency than aluminium alone. Copper has considerably higher warmth conductivity, and with the flexibility of the half to be soldered, warmth switch could be additional improved by as a lot as 20%. Using a copper coating also can assist keep away from sizzling spots that may cut back car effectivity, cut back vary and reduce the lifetime of the car because of overheating. And the largely aluminium-based half can nonetheless ship elevated vary.

Whereas chilly spraying of warmth sinks has been a typical software over the previous couple of a long time, the spraying of a copper coating onto aluminium is comparatively novel. The automotive business now wants a cheap resolution that’s extremely environment friendly and efficient.

Subsequent era chilly spraying for subsequent era automobiles

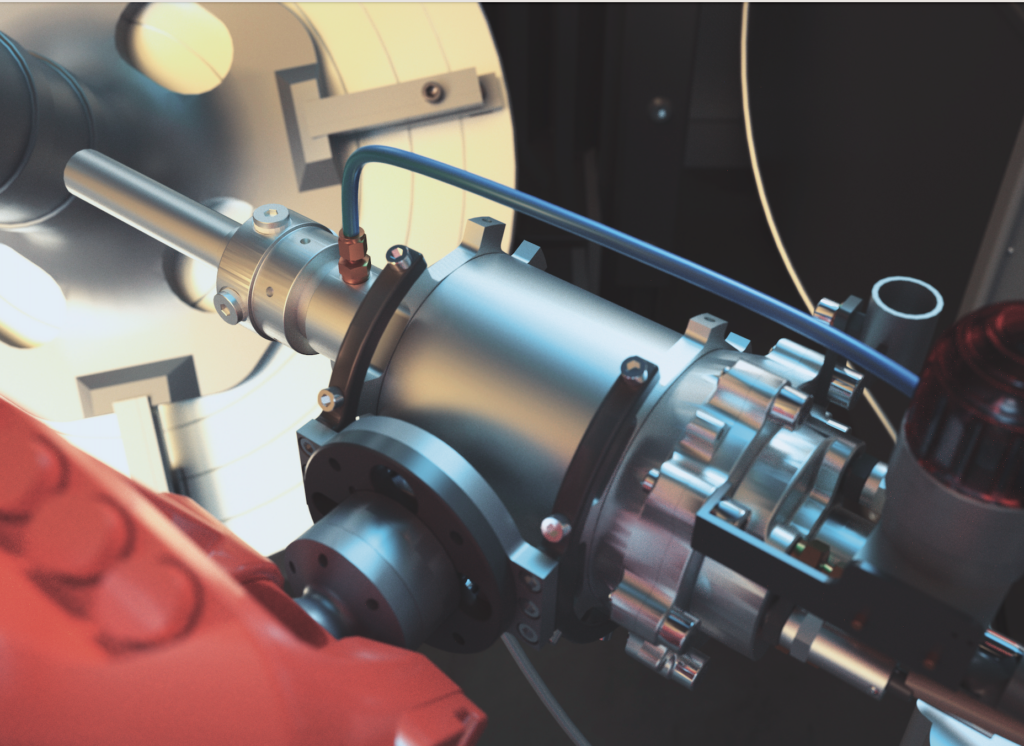

Chilly spraying is a fabric deposition approach the place tiny steel particles of between 5 to 50 microns are propelled onto a substrate—on this case the brake—utilizing high-pressure gases. The particles, which start their life at ambient temperatures, are positioned in a nitrogen or helium gasoline stream which is then heated and accelerated by means of a supersonic nozzle at unbelievable speeds of between 500 to 1200 meters per second. Throughout the course of, the temperature of the steel powder stays far beneath its melting level, guaranteeing the steel particles keep of their stable stage, so retain their distinctive properties and stay oxidation resistant. The coating created by way of this course of is ductile which additionally prevents any threat of embrittlement underneath stress.

As a result of excessive temperatures required (as much as 1,100 levels Celsius) throughout the gasoline stream, the manufacturing of coated merchandise is closely depending on quite a few elements, together with the availability of excessive purity gases and a secure and dependable gasoline circulate with minimal stress variation—all of which should be inside a specified temperature vary. Speedy temperature modifications can harm each the gasoline heater and the nozzle on the tip of the spray gun. A relentless, dependable stress is required to make sure a easy gasoline circulate which can finally affect the coating high quality. Any fluctuations can doubtlessly have an effect on delivering a uniform coating and finally a unfavorable impact on total product high quality.

That is the place the Linspray Join system is available in to play. Develped by Linde in collaboration with German chilly spraying know-how agency Influence Improvements, Linspray is designed to make sure the supply of a dependable, secure and high-quality gasoline circulate with minimal variation. The revolutionary system permits automotive producers to watch such course of parameters as stress, temperature and filling ranges of the nitrogen tank. It additionally has the potential to routinely ship error messages in actual time and may change to an emergency gasoline provide or activate a protected shut-down of the system in case of incidents. And manufacturing volumes can simply be elevated or decreased as required.

Such enhanced capabilities is not going to solely allow automotive producers to cheaply meet new particulate emissions laws once they do come into drive, however also can enhance brake corrosion resistance, offering OEMs with a aggressive benefit. For EV drivers, it means they are often assured that their selection of electrical automobile could make an actual contribution to the discount of air air pollution in addition to benefitting from better driving vary and fewer upkeep.

In regards to the authors: Werner Krömmer oversees Enterprise Improvement, Manufacturing Trade, at Linde Applied sciences. Paolo Kirchpfening is International Commercialisation Supervisor at Linde Applied sciences